Insolia® Intellectual Property

Protecting Innovation Through Comprehensive Patent Coverage

Insolia Technologies are biomechanically-based footwear innovations that optimize foot position, alignment, and flexibility. Each technology is grounded in gait science and foot anatomy, resulting in patented designs that enhance comfort and reduce injury risk.

We obtain one or more utility patents on all Insolia Products and Technologies we bring to market. We currently hold 27 Utility Patents and 4 Design Patents (31 total) in the United States, including their international counterparts in Europe, China, Japan, and other key markets. Another 15 utility patents are pending.

All customers receive comprehensive IP protection through our licensing agreements..

Finally, we have a global network of local patent attorneys who assist us and our customers in the event of any potential infringement.

Core Technologies

We adapt our patented technologies for a wide range of products. Global manufacturers implement Insolia Flex and Insolia Cradle across all footwear categories, from athletic shoes to high heels and sandals.

Over 60 million pairs of footwear with Insolia Technologies have been sold.

Exclusive licensing of Insolia Technologies provides manufacturers with protected differentiation in competitive markets.

Patents Issued & Pending

Insolia IMS - Cleated Athletic Footwear

Notice of Allowance Received

Insolia Integrated Motion System technology represents our latest innovation in sports injury prevention, specifically addressing the epidemic of non-contact ACL injuries in cleated footwear.

Our patented approach revolutionizes cleat design by biomechanically optimizing stud placement to preserve natural foot motion while maintaining traction. Unlike conventional cleats that restrict the Great Toe Joint, Insolia IMS enables proper joint flexion during high-force athletic maneuvers.

Key Innovations:

Insolia Radial Stud Array™ (RSA): Single center of rotation aligned with the foot's natural pivot point

Insolia Free Motion Zone™ (FMZ): Studs positioned around, not under, the Great Toe Joint

Insolia Zone of Flexibility™ (ZOF): Flexible zone in the outsole for natural foot bending

Insolia Pressure Relief Dome™ (PRD): Air gap protection prevents upward pressure on critical joints

Development Status:

Functional prototypes completed. Biomechanical testing validated. Seeking manufacturing partners for commercialization.

The first Insolia Cleat Prototype

For complete technical specifications and biomechanical data, see our Insolia IMS homepage

Insolia Flex, Flex Plus, and Flex Max Technolgies

Our patented Flex technologies enhance natural foot motion by allowing the Great Toe Joint to move freely, triggering the body's natural arch support mechanism.

Core Innovation:

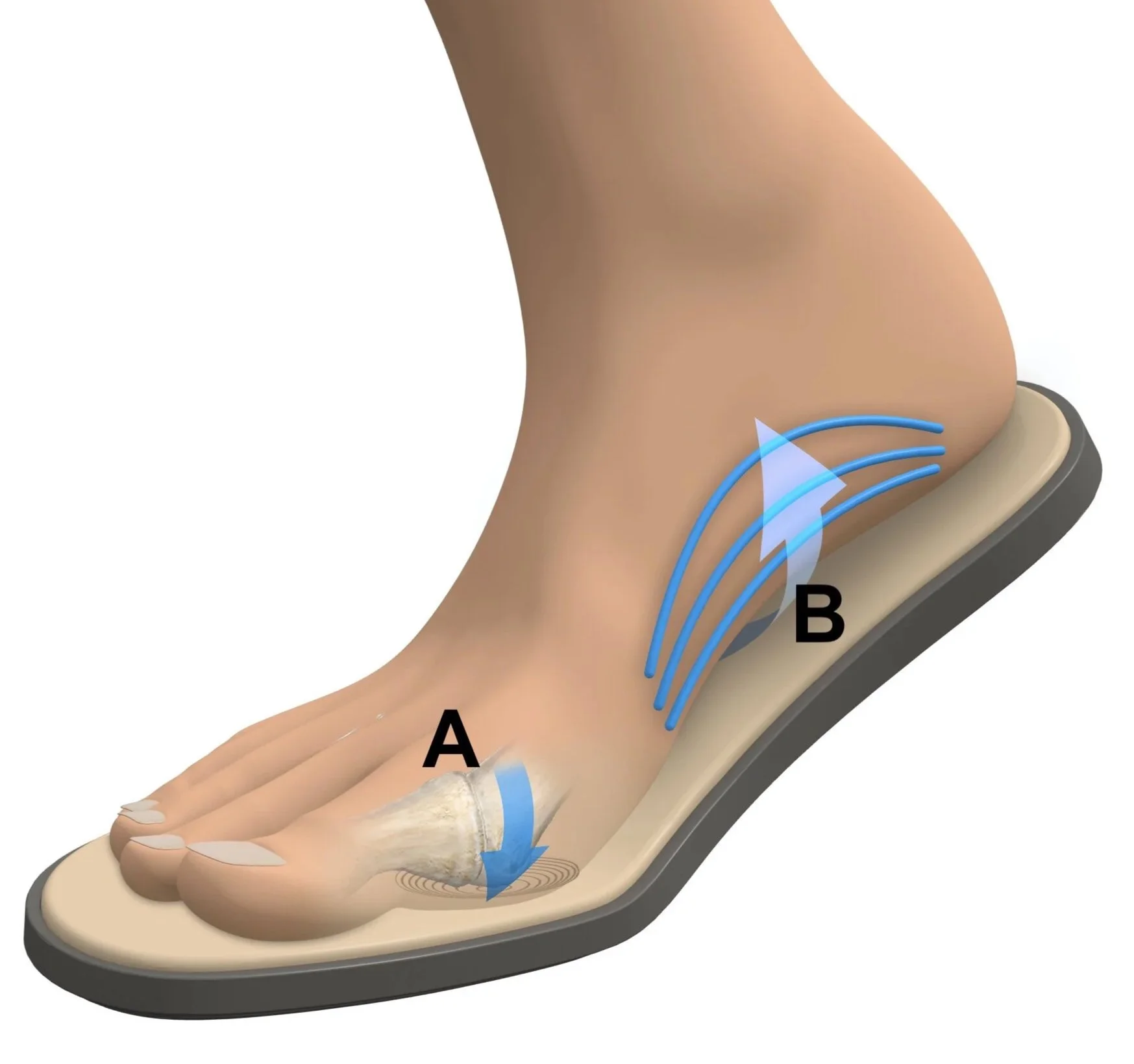

The asymmetric depression under the Great Toe Joint allows it to drop and rotate naturally during walking. This preserves the foot's ability to store and release energy through dynamic arch flexing - unlike fixed arch supports that restrict natural motion.

Insolia Flex Technologies

• Enhanced Flexibility

• Dynamic Arch Support

Proven Benefits - Walking/Athletic Shoes:

40% increase in forefoot comfort scores

10% improvement in walking efficiency (reduced VO2/kg)

Natural, dynamic arch support through the Windlass mechanism (B)

Reduced compensation stress on legs and lower back

Technology Variations:

Insolia Flex - Base technology for enhanced forefoot flexibility

Insolia Flex Plus - Adds metatarsal support and enhanced pressure distribution

Insolia Flex Max - Trim-to-fit insole (one-size-fits-many solution)

Additional Benefits in High Heels (Flex Plus):

Enhanced stability while standing and walking

Better pressure distribution across the forefoot

Reduced burning sensation in the ball of the foot

Insolia Cradle Technology

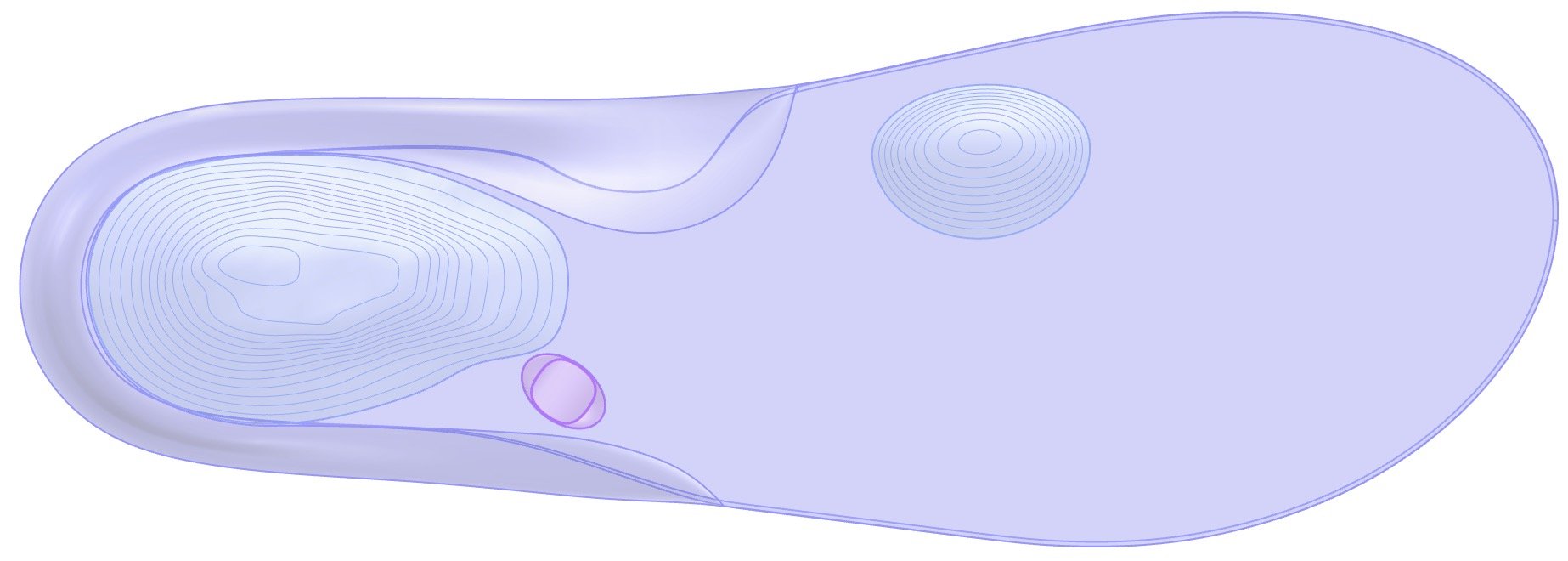

Insolia Cradle corrects a fundamental oversight in footwear design: while heel cups are symmetrical, the human heel bone (calcaneus) is not. Our patented technology provides the first anatomically-matched heel cup design.

Core Innovation:

Asymmetric heel cup contours that match the natural shape of the calcaneus, with extended medial support to reduce plantar fascia strain.

Insolia Cradle technology shown in a sandal application

Benefits in Walking/Athletic Footwear:

Improved balance and stability platform

Reduced plantar fascia strain through medial arch support

Enhanced standing and movement comfort

Better proprioceptive feedback

Benefits in High Heels:

Enhanced balance during standing and walking

Improved weight distribution

Increased overall comfort

Insolia Flex Max Technology

Insolia Flex Max delivers our patented biomechanical benefits in an affordable,

one-size-fits-many format for the mass market.

Design Innovation:

Polyurethane molded construction for durability and minimal thickness

Hexagonal perforation pattern reduces weight and cost while providing ventilation

Incorporates both Insolia Flex Plus and Insolia Cradle technologies

Trim-to-fit design covers US Men's sizes 8-13 (five trim lines)

Technical Features:

Variable-depth hex perforations optimize flexibility and support zones

Adapted Great Toe Joint depression accommodates six full-size ranges

Ultra-thin heel cup design incorporates modified Insolia Cradle geometry

Maintains biomechanical benefits across the entire size range

Market Position:

Unlike basic cushioning insoles, Flex Max provides measurable biomechanical improvements at a competitive price point for mass retail distribution.

Insolia® Foundation Products

Insolia Foundation represents our core technology platform for OEM manufacturers and brands seeking to incorporate proven biomechanical innovations into their own footwear designs.

Product Applications:

Insoles: Complete drop-in solutions for dress shoes, casual footwear, and athletic shoes

Outsoles: Licensed technology integration for athleisure and performance footwear

Hybrid Solutions: Combined insole/midsole implementations for maximum benefit

Technology Integration Options:

Insolia Flex Only: Enhanced forefoot flexibility and walking efficiency

Insolia Cradle Only: Anatomically correct heel support and stability

Combined Technologies: Maximum biomechanical benefit through both systems

Insolia Foundation Insole for Men’s Dress Shoe

Insolia Foundation Outsole for Athleisure Shoe

Commercial Models:

Direct purchase of manufactured insoles with embedded technology

Patent licensing for in-house outsole/midsole production

Co-development partnerships for custom applications

Target Markets:

Dress shoes, Casual footwear, Athleisure,

Work boots, Athletic shoes.

Insolia Plantar Fasciitis Relief Technology

Our latest patented innovation specifically addresses plantar fasciitis, one of the most common causes of heel pain affecting millions worldwide.

Insolia Plantar Fasciitis Insole showing three integrated technologies: optimized Cradle heel cup, 45-degree Cuboid Pad, and Flex depression under Great Toe Joint

Development Background: Consumer feedback from our "Goldie Lou" sandal users indicated significant plantar fasciitis pain relief, inspiring targeted optimization of our technologies for this specific condition.

Three-Technology Integration:

Optimized Insolia Cradle: Enhanced medial extension specifically calibrated to reduce plantar fascia tension

Novel Cuboid Pad: Patented support with groove aligned to the peroneus longus tendon axis, providing lateral column stability

Insolia Flex: Enables natural Great Toe Joint motion to reduce compensatory stress

Clinical Benefits:

Reduced tension on the plantar fascia during weight-bearing

Improved load distribution across the foot

Enhanced midfoot stability through cuboid support

Decreased morning pain, as typical of plantar fasciitis

Target Market: Therapeutic insoles, comfort footwear, recovery sandals.

Insolia Components for OEM Use

Insolia offers proven biomechanical components for direct integration into manufacturers' footwear designs, available through licensing or direct supply agreements.

Implementation Support:

Technical integration assistance

Manufacturing process consultation

Co-development for custom applications

Full IP protection under licensing agreements

Insolia Flex Plus Component

Advanced forefoot flexibility with integrated metatarsal support

Ideal for comfort, athletic, and therapeutic footwear

Insolia Heels I-4 Component

Complete high-heel comfort system

Combines Insolia Cradle and Flex Plus technologies

Proven 25% weight redistribution from forefoot to heel

Four sizes cover US women's 4-12

Summary

Technical Foundation: Twenty-five years of biomechanical research have produced a portfolio of technologies addressing specific footwear problems. Each solution is based on gait analysis data and validated through independent laboratory testing.

Manufacturing Integration: All Insolia technologies work with standard footwear production methods. Implementation requires no special equipment or significant process changes. This approach has facilitated adoption in over 60 million pairs globally.

Intellectual Property Portfolio: 31 issued patents and 15 pending applications across the United States, Europe, and Asia. Patent coverage extends through 2038, providing long-term protection for licensing partners.

Application Range: Technologies proven effective across all footwear categories: athletic, casual, dress, and therapeutic.

Technical Support: HBN Shoe provides implementation guidance, manufacturing consultation, and ongoing technical assistance to ensure the successful integration of licensed technologies.

For licensing inquiries, please contact us.